Magnetic field sensors are used in nearly every industry and the same sensor can be used for a wide variety of applications. For example, our Quadrature Magnet Sensors are used for monitoring concrete truck drum rotation, measuring feed of hose into mine shafts, tracking the rotational position of rotating components in heavy equipment, and tracking winch feed on Research vessels (just to mention a few applications). However, over the years we have developed some product lines to solve specific problems in dedicated applications.

There were no results for "".

If you are searching for a part number from a sensor engraving, you may be including a date code, gear pitch, or programming code.

Try searching again without any characters after an "_" or a blank space on the markings.

You may also find the product or information you need on one of the below pages:

For immediate assistance, please call us at: 970-879-9900.

Application Specific Sensors

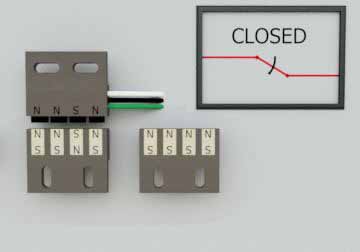

Coded Alignment Sensing Systems

Coded Alignment Sensing Systems were developed for applications where equipment operators were disabling safety sensors using household magnets to falsely indicate that protective doors are closed before activating potentially dangerous equipment.

These sensors combine multiple Hall Effect switches and magnetic targets that must all be properly aligned for the sensor output to switch, preventing the equipment operator from bypassing the safety mechanisms in the equipment using any magnets other than the one provided with the system.

Magnetic Tape Tracking Sensors

Magnetic Tape Tracking Sensors were developed for guiding Automated Guided Vehicles (AGVs) and Automated Guided Carts (AGCs). Using specially programmed Hall Effect sensors and signal processors these sensors provide analog and digital signals to the AGV or AGC control system to guide the motors on the vehicle for keeping it centered over magnetic tape mounted to the floor.

By utilizing non-contact magnetic sensors and a cost effective flexible magnetic tape AGV and AGC routes can be set and moved quickly and easily, allowing for much more flexibility than other AGV/AGC guidance systems. We provide sensors direct to manufacturers for their custom vehicles and OEM sensors for companies offering complete AGVs and AGCs.

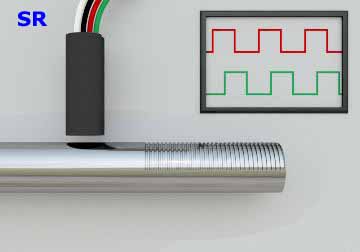

Shot Rod Sensors for Die Casting Equipment

Sensor Solutions has been manufacturing high speed, precision calibrated Shot Rod Sensors for die casting systems since the 1990s. We work directly with OEM die cast machine manufacturers to provide the best sensors and customer support in the industry and also provide drop-in replacement sensors for replacing Visitrak sensors direct to numerous die casting facilities.

NEW FOR 2016: Sensor Solutions now offers shot rod sensors with internal high-speed logic to monitor the signal provided by the target rod and update sensor calibration as required to ensure the best quadrature signal is provided to the control system for tracking the speed and position of the shot rod during operation. Our SSCR20TPI and SSCR2MM sensors can be found here.

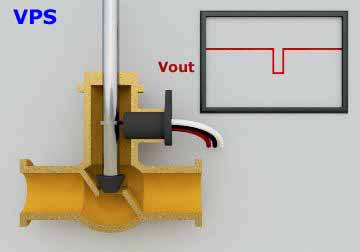

Valve Position Sensors

Valve Position Sensors are precisely calibrated back-biased Hall Effect sensors designed specifically to detect the position of steel pins inside of valves or count the number valve strokes. They provide a digital output that turns on when the valve pin moves towards the sensor. Our standard catalog options are designed to turn the output on from a 0.030” diameter pin at 0.060” from the sensor face.

These sensors can be custom calibrated to the specific pin within your valve. Custom packaging, connections, and product labeling are available for OEM valves as required.

New Custom Applications

In addition to the product lines above Sensor Solutions provides custom non-contact solutions for many different industries and applications. We have thousands of options for detecting speed, position, count, direction of motion, angular position, proximity, and alignment. Contact our applications engineers to discuss your specific product requirements.