Magnetic Digital Count Sensors

Gear, Winch, Drum & Linear Feed Measurement

Sensor Solutions offers a variety of magnetic digital count sensors to measure a count with or without direction such as gear, winch, drum & linear feed measurement. The output pulses from Hall Effect Sensors, proximity switches, and gear tooth sensors can track count for each digital switching event using a Counter or PLC. Counters can be scaled to track and display a number of event cycles, track a position, measure the amount of linear feed, or track a position within rotation. To learn more about our magnetic digital count sensors, and our gear, winch, drum,and linear feed measurement, contact our engineers today.

There were no results for "".

If you are searching for a part number from a sensor engraving, you may be including a date code, gear pitch, or programming code.

Try searching again without any characters after an "_" or a blank space on the markings.

You may also find the product or information you need on one of the below pages:

For immediate assistance, please call us at: 970-879-9900.

- Home

- >

- Sensors by Function

- >

- Measure Count

Measure Count

-

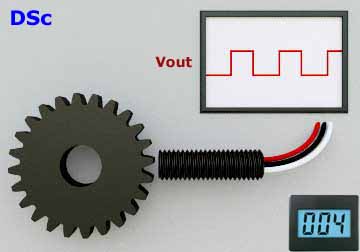

Hall Effect Sensors for Counting Gear Teeth

-

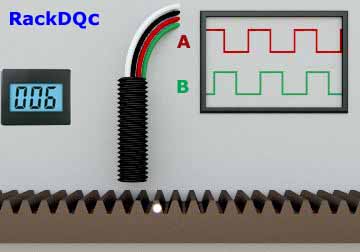

Hall Effect Sensors for Counting Teeth on a Rack Gear

-

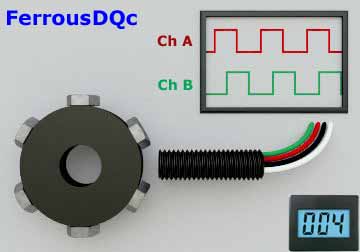

Hall Effect Sensors for Counting Ferrous Targets

-

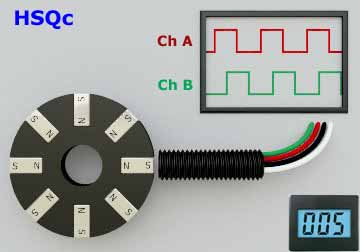

Sensors for Counting With Magnets

-

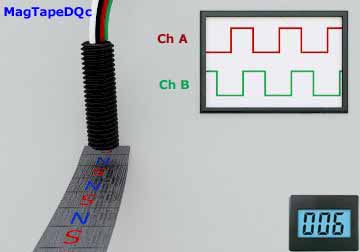

Counting/Position Tracking Sensors Detecting Multi-Pole Magnet Tape

-

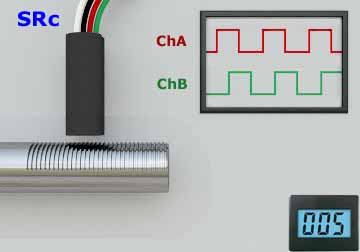

Directional Counting Sensors for Detecting Die Casting Shot Rods

Digital Count Sensors for Detecting Magnetic Targets

How do I choose between single-channel and quadrature magnet sensors for counting magnetic targets?

By attaching one or more magnets to a moving target, Hall Effect Switches can be mounted to track a relative count when the magnet(s) pass the sensor face.

- Single Channel Hall Switches provide 1 digital output that will pulse each time the magnet passes the sensor face. For event counting applications, or applications where direction does not change or direction change does not matter these are the lowest cost options for tracking a count.

- Quadrature Magnet Sensors provide two out of phase digital pulse trains, a programmed Counter compares which output detects the magnet first and then will count up or down accordingly.

What are the benefits of each option?

Permanent Magnets and Hall Effect Switches will work with significantly greater gaps than gear tooth sensors. The following Application Note provides charts showing operate gap ranges for different sensor types and magnet sizes. Magnets can also be detected through non-ferrous target such as aluminum or plastic cases.

Target magnets are available with the South Pole Marked for use with our sensors. Magnets are also available mounted into bolts and other threaded targets for easy installation or built into two piece clamping collars for mounting direct to rotating shafts.

Digital Count Sensors for Detecting Steel Targets

What are the differences between Single Channel Gear Tooth Sensors and Single Channel Target Tracker Sensors for counting steel targets?

Spur gears, rack gears, pulleys, and other ferrous targets such as tone rings or bolt heads can be targeted to track a count for applications such as measuring winch feed lengths, number of rotations, or timing other components in a system based on the position of the target within a rotation or linear movement. These Hall Effect Gear Tooth and Target Tracking Sensors are available in the following configurations:

- Single Channel Gear Tooth Sensors will provide 1 pulse each time a tooth from the gear passes the sensor face for tracking count where direction does not change or change of direction does not matter.

- Single Channel Target Tracker Sensors will provide 1 pulse each time a steel target such as a bolt head passes the sensor for tracking a count where direction does not change. These sensors can also track holes in steel targets.

- Quadrature Gear Tooth Sensors provide two out-of-phase digital pulse trains when wired to a programmed Counter direction is resolved by determining which output detects the target first to increase or decrease the count.

- Ferrous Metal Proximity Sensors detect steel targets over a wider gap range than Target Tracker sensors. They provide 1 pulse each time a steel target such as a bolt head passes the sensor for tracking a count where direction does not change. These sensors can also track holes in steel targets.

How do Quadrature Gear Tooth Sensors work? And how do they determine direction when counting steel targets?

Note: Quadrature Gear tooth sensors are built and calibrated specific to the target form they are detecting, several Application Notes are available on our Resources page describing why this is important and how to design targets for directional or non-directional counting.

If you do not find the speed and direction sensor or target you need in our catalog, contact our engineers to discuss a custom solution.