Magnetic Detection

Tracking alignment between two components of a system can be accomplished with a variety of magnetic sensor types such as magnetic detection & alignment sensors. Hall effect switches and analog hall effect sensors paired with magnets can confirm alignment between a sensor and magnet. Sensors are also available for digital and analog alignment detection of ferrous targets or for tracking changes in alignment dictated by a rotating gear.

There were no results for "".

If you are searching for a part number from a sensor engraving, you may be including a date code, gear pitch, or programming code.

Try searching again without any characters after an "_" or a blank space on the markings.

You may also find the product or information you need on one of the below pages:

For immediate assistance, please call us at: 970-879-9900.

Digital Switching Sensors for Alignment Detection

Sensors are available with digital switching outputs that turn on (or open/close a relay) when the sensor is aligned to either a magnet or steel target.

- Single Channel Hall Switches switch on when a magnetic field of the proper pole is near the sensor. Dual Output Hall Switches provide an output for each magnetic pole allowing for detecting alignment of two different targets from a single sensor using 2 magnets with the opposite poles facing the sensors..

- Reed Switches open or close as a relay dependent on the proximity of a magnetic field. These are passive magnetic switches that do not require their own power, but the sensor life is dependent on the amount of power they are switching.

- Coded Alignment Sensing Systems are tamper-proof Proximity Sensors for uses in applications where the end user may try and fool the system that the target is properly aligned using a different magnet.

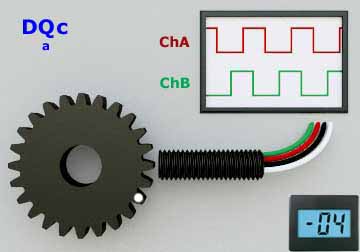

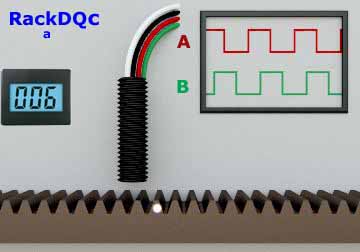

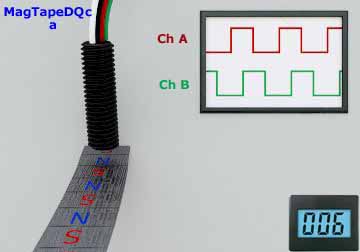

- In applications where a gear rotates or a rack gear moves to adjust alignment Quadrature Gear Tooth Sensors when wired to a programmed Counter can translate the rotational or linear movement of the gear teeth to how much each gear tooth passing adjusts the alignment.

Analog Sensors for Monitoring Alignment

Analog Hall Effect Sensors and Analog Ferrous Metal Position sensors can be used to determine alignment by detecting either magnetic or steel targets passing by the face of the sensor.

- Ferrous Metal Position Sensors provide an analog output that increases as steel approaches or passes by the sensor face. 275VPA sensors can be programmed specific to the target being detected to provide an analog output that is at it’s maximum when a shaped target is centered in front of the sensor. Larger analog ferrous metal position sensors are able to detect steel targets at gaps up to 3.5”.

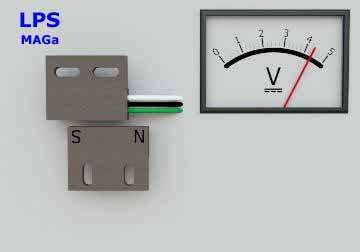

- Analog Hall Sensors provide an analog output that increases or decreases as the magnetic field changes. When detecting a magnetic pole the field will be greatest when the sensor is centered over the magnet.

When using magnets and Hall Effect Switches or Analog Hall Sensors the size shape, and material of the magnet will determine the output state at a given gap. This Application Note provides charts showing operate gap ranges for Hall Effect switches and also detail magnetic field strengths that can be used to calculate analog sensor voltages. Magnets can also be detected through non-ferrous target such as aluminum or plastic cases.

Target magnets for proximity measurement are available with the South Pole Marked for use with our sensors. Magnets are also available mounted into bolts and other threaded targets for easy installation or built into two piece clamping collars for mounting direct to rotating shafts.

If you do not find the alignment sensor you need in our catalog, contact our Engineers to discuss a custom solution.