Speed & Direction Sensors

Precision Gear Tooth, Steel, & Magnetic Target Tracking

Sensor Solutions offers a variety of speed and direction sensors to measure rotational or linear speed and the direction of travel. Once you choose a target from the list on this page, you will be directed to hall effect sensors with two or more outputs for resolving both speed and direction of motion. You will be able to select from a wide range of precision gear tooth, steel, and magnetic target tracking in our catalog. To order speed and direction sensors, request a quote today!

There were no results for "".

If you are searching for a part number from a sensor engraving, you may be including a date code, gear pitch, or programming code.

Try searching again without any characters after an "_" or a blank space on the markings.

You may also find the product or information you need on one of the below pages:

For immediate assistance, please call us at: 970-879-9900.

- Home

- >

- Sensors by Function

- >

- Measure Speed and Direction

Measure Speed and Direction

-

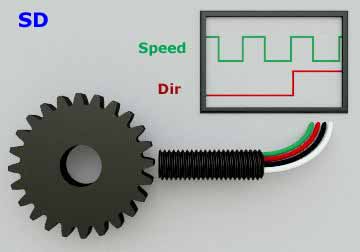

Speed and Direction Sensors for Detecting Gears

-

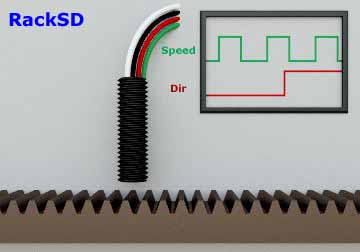

Speed and Direction Sensors for Detecting Rack Gears

-

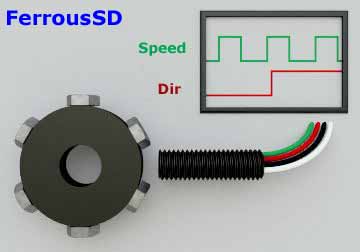

Speed and Direction Sensors for Detecting Ferrous Targets

-

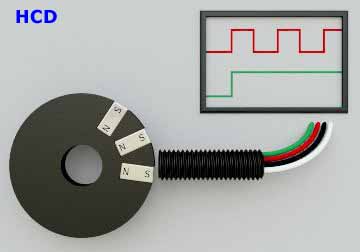

Speed and Direction Sensors for Detecting Magnets

-

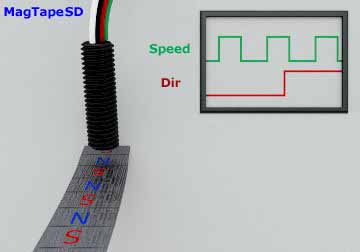

Speed and Direction Sensors for Detecting Multi-Pole Magnet Tape

-

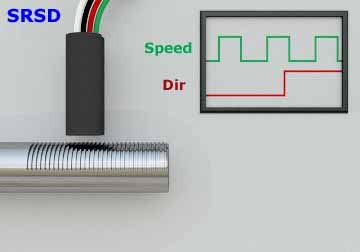

Speed and Direction Sensors for Detecting Die Casting Shot Rods

Speed & Direction Sensors for Detecting Steel Targets

In which Configurations are Hall Effect Switches Available?

Speed and direction of movement of gears, rack gears, and other ferrous targets such as tone rings or bolt heads can be measured using multi-channel gear tooth sensors. These Hall Effect Switches are available in the following configurations.

- Quadrature Gear Tooth Sensors provide two out of phase digital pulse trains, when connected into a properly programmed Tachometer direction is resolved by determining which output detects the target first.

- Speed and Direction Gear Tooth Sensors internally compare the pulses from the sensing elements and provide one speed output and one direction output that is high in one direction of motion and low in the other.

- Speed Direction Quadrature Gear Tooth Sensors combine the functionality of the two sensors above and provide three total outputs; the two out of phase speed pulse trains and the high/low direction output.

Quadrature and Speed/Direction Gear tooth sensors are built and calibrated specific to the target form they are detecting, several Application Notes are available on our Resources page describing why this is important and how to design targets for magnetic speed and direction monitoring.

Speed & Direction Sensors for Detecting Magnetic Targets

Using these magnet sensors, how can I detect both speed and direction when I don't have gears?

For detecting speed and direction where a gear or similar target is not available, one or more magnets can be attached to the target and multi-channel Hall Effect switches can be used.

- Quadrature Magnet Sensors provide two out-of-phase digital pulse trains, when connected into a properly programmed Tachometer direction is resolved by determining which output sees the magnet first.

- Speed and Direction Magnet Sensors internally compare the pulses from the sensing elements and provide one-speed output and one direction output that is high in one direction of motion and low in the other.

What are the Advantages of Using Magnets?

An advantage of using magnets is that the gap between the sensor face and the magnets can be much greater than sensors for steel targets. The following Application Note provides charts showing operating gap ranges for different sensor types and magnet sizes.

Target magnets are available with the South Pole Marked for use with our sensors. Magnets are also available mounted into bolts and other threaded targets for easy installation or built into two-piece clamping collars for mounting directly to rotating shafts.

If you do not find the speed and direction sensor or target you need in our catalog, contact our Engineers to discuss a custom solution.